Direct Numerical Simulation of Turbulent Combustion

Using the direct numerical simulation code TTX (TokyoTech Combustion Simulation), developed in our laboratory, we perform a wide range of DNS studies on turbulent combustion. The following sections describe our activities in the order of .

1. Research Background

Over the next 30 years, it is projected that more than 80% of the world’s total energy supply

will continue to come from combustion-based systems*1.

Although combustion devices have been used and improved for more than two hundred years since the late 1700s,

modern environmental regulations and the potential depletion of fossil fuels demand further innovation.

To realize hydrogen clean combustion with zero CO₂ emissions,

or to achieve higher energy output using more compact combustors,

it is essential to control turbulence effectively and promote the mixing of fuel, air, and hot burned gases.

This requirement is particularly significant for automotive engines and gas turbines for aircraft.

However, while controlled turbulence promotes mixing and enables low-emission combustion,

the turbulence field itself is strongly affected by combustion-induced gas expansion and changes in thermophysical properties.

Understanding the interaction between turbulence and chemical reactions is indispensable

for developing next-generation low-emission combustors

as well as for constructing accurate combustion models used in simulations.

*1US Energy Information Administration, Annual Energy Review, 2010

2. What is Direct Numerical Simulation?

Turbulent combustion phenomena are governed by systems of several to hundreds of coupled partial differential equations.

These governing equations contain strong nonlinearities and require the resolution of a wide range of physical scales.

Therefore, high-accuracy numerical schemes with significant computational cost are required.

Such simulations are called Direct Numerical Simulation (DNS)

and they play a critical role in developing the turbulence–combustion interaction models used in engineering design.

Our laboratory performed the world’s first DNS incorporating detailed chemical kinetics in the 1990s*2.

Since then, we have used supercomputers to generate extensive DNS databases, which are used to understand combustion physics,

develop models, and contribute to the turbulent combustion community by sharing data with other research groups.

*2 T. Poinsot and D. Veynante, Theoretical and Numerical Combustion, 2005.

3. Turbulent Combustion Models

In contrast to DNS, simulations used for practical combustor design rely on simplified governing equations and focus on the mean flow field or large-scale unsteady motion. These approaches are known as RANS (Reynolds-Averaged Navier–Stokes) and LES (Large Eddy Simulation). Turbulent combustion models are essential for closing these simplified equations and greatly affect simulation accuracy. Since turbulence–combustion interactions are strongly nonlinear, developing reliable models is challenging. Our laboratory develops physics-based turbulent combustion models using extensive DNS databases rather than relying solely on empirical assumptions.

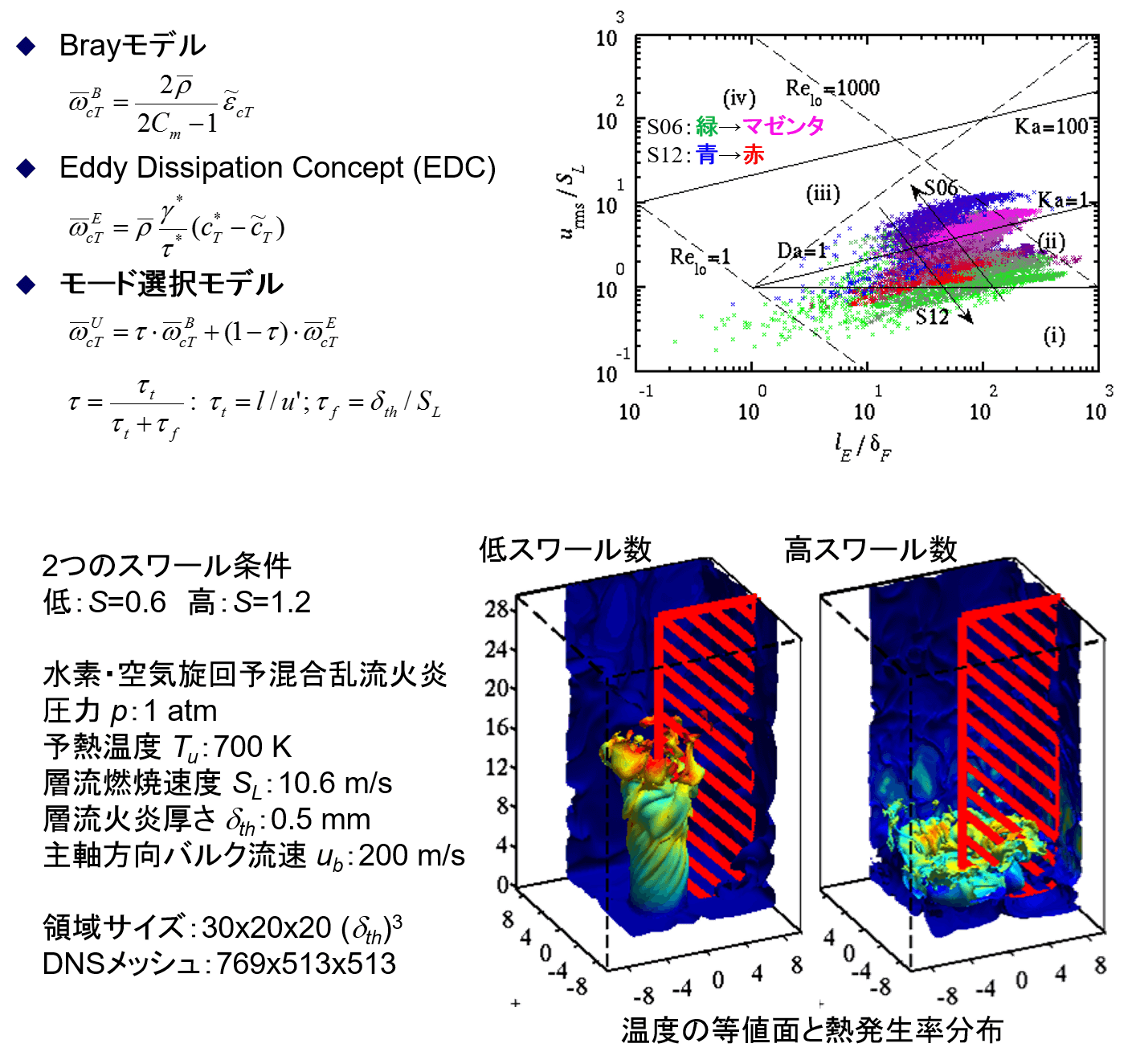

4. Turbulent Combustion Models Developed in Our Laboratory

Based on DNS results and theoretical analysis of turbulent and turbulent reacting flows, our laboratory has developed several turbulent combustion models for LES and RANS simulations, including:

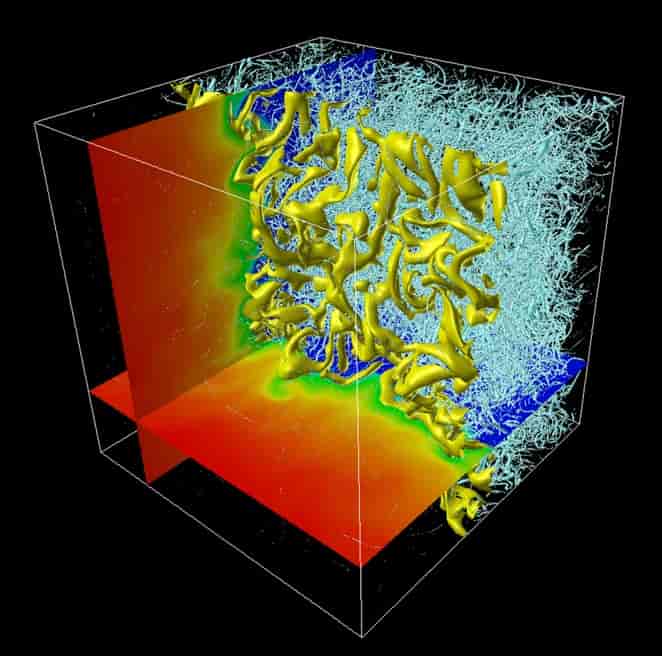

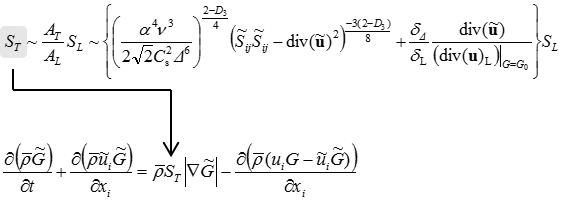

Fractal–Dynamic SGS Combustion Model

The Fractal–Dynamic SGS model shown above is an SGS combustion model used in LES to close the G-equation (lower equation), which is often used in place of the transport equation for flame surface density.

This model has been selected for implementation in multipurpose simulation software, including the Japanese national SIP program’s “HINOCA” thermo-fluid analysis platform.

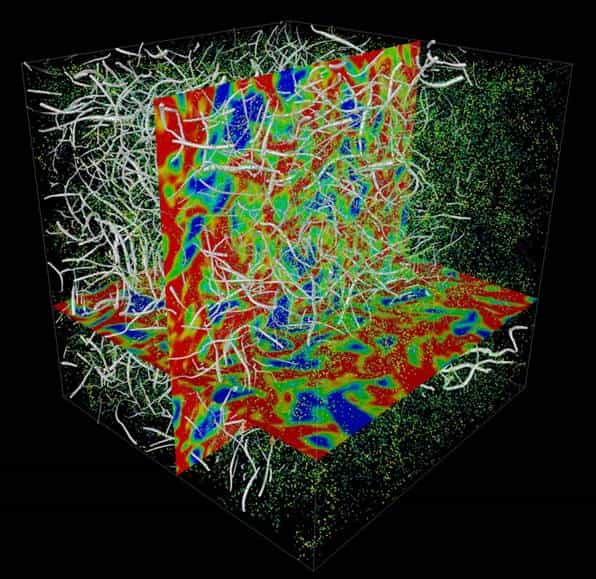

Mode Selection Model

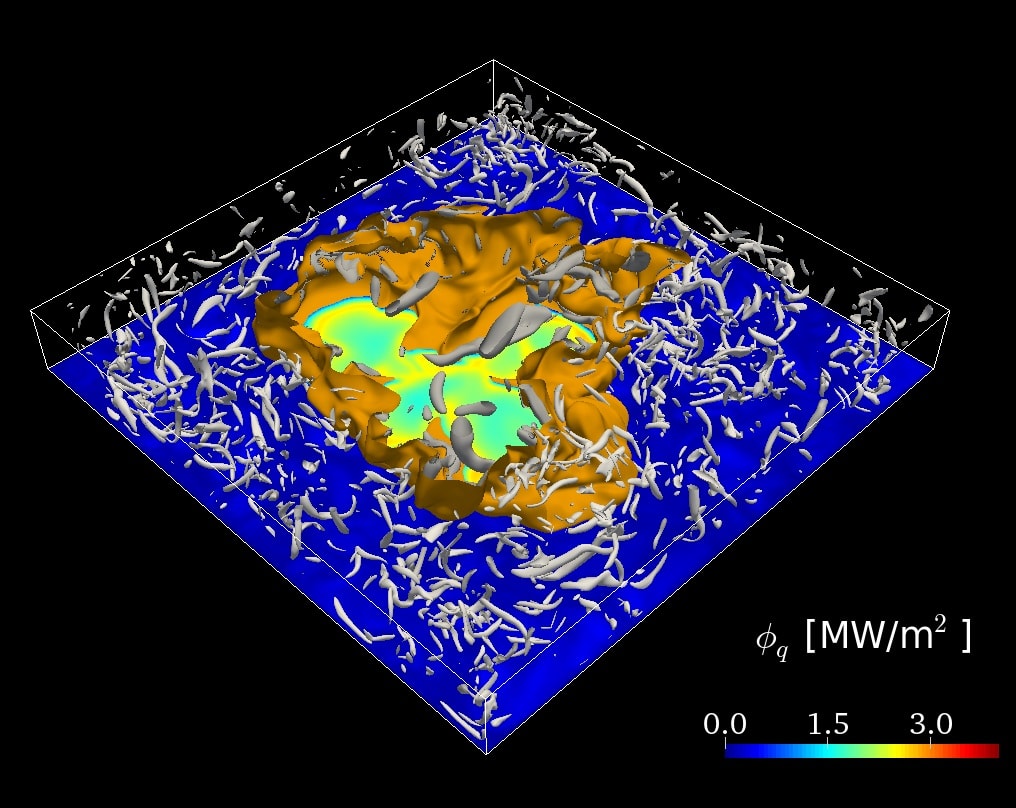

The mode selection model (left) describes source terms in RANS simulations. It extends conventional combustion models—normally valid only for a single turbulence regime— to complex local conditions where multiple regimes coexist. The model was validated using DNS of a swirling turbulent premixed combustor (bottom). It is adopted in the Combustion Analysis Platform Development Working Group of the Combustion Society of Japan.

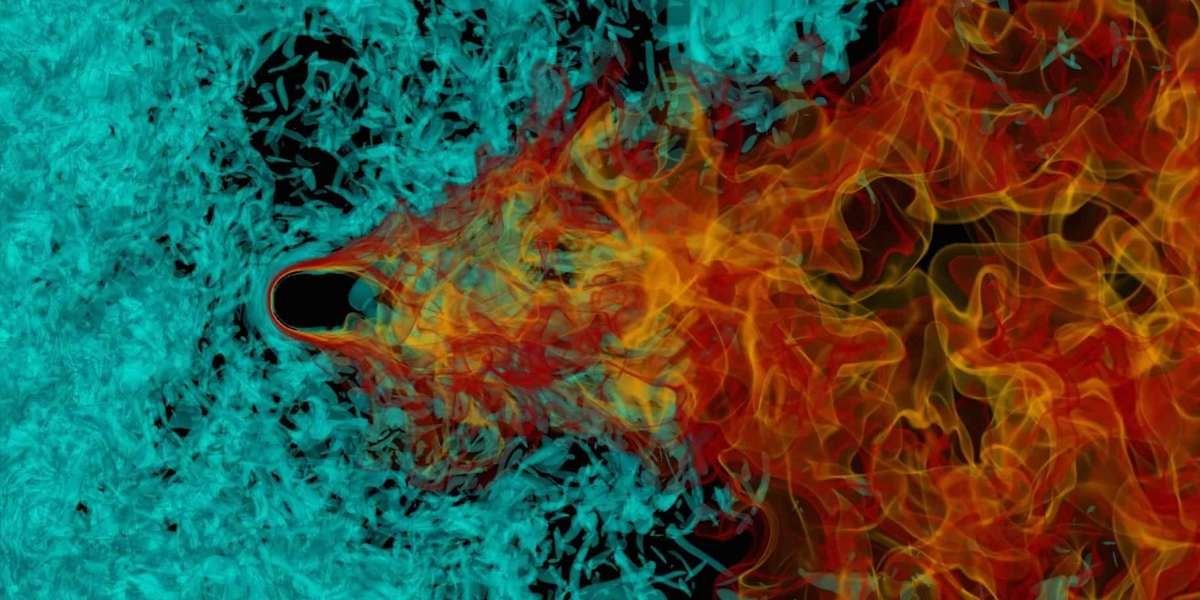

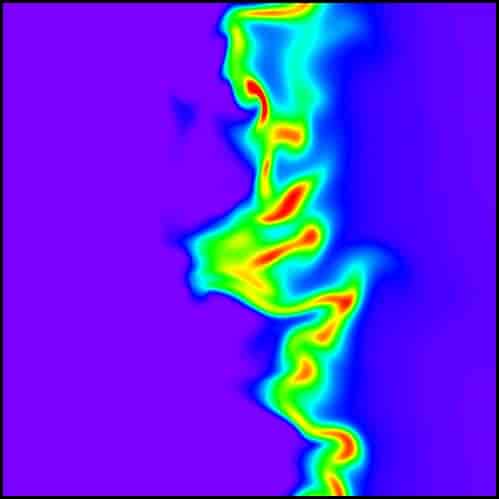

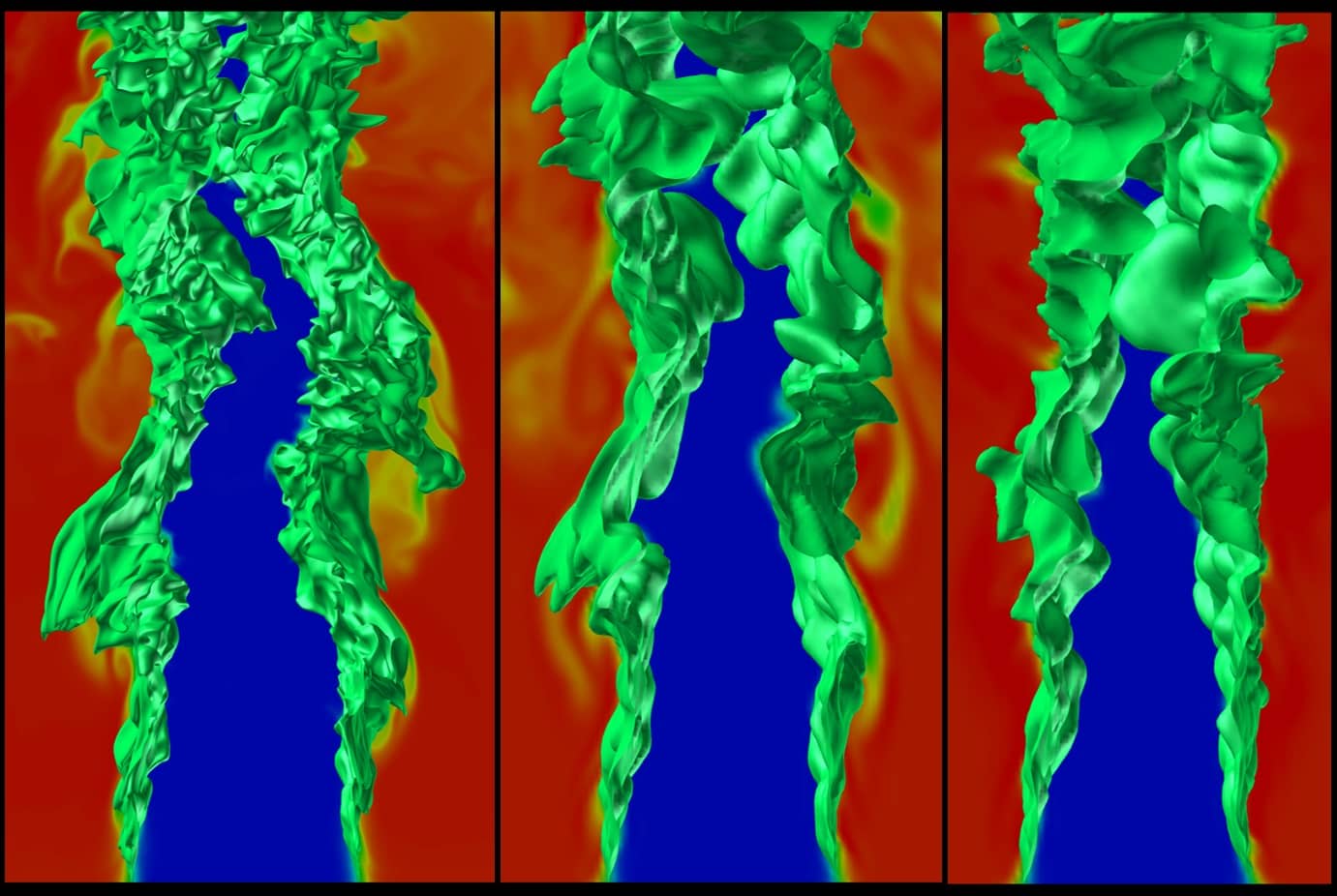

4. Representative DNS Results Conducted in Our Laboratory